How Optimised Delivery Routes Improve Driver Retention and Satisfaction

Table of Contents

- Optimised Delivery Routes and Driver Retention

- Why Driver Retention Matters

- The mechanics: How optimised delivery routes improve driver satisfaction & retention

- Integrating Route Optimisation into your Driver Retention Strategy

- Supportive retention strategies: Beyond routes

- Measuring success: KPIs and metrics

- Challenges, risks, and caveats

- Conclusion

- Your next steps to driver retention

Optimised Delivery Routes and Driver Retention

One of your best delivery drivers just handed in their notice.

Not because of pay. Not because of the hours. But because of chaotic routes that make no sense, impossible schedules, and the daily frustration of being set up to fail. The replacement will cost you around £5,000 in recruitment and training. And so the cycle continues.

Driver turnover is one of the most expensive operational challenges in logistics, yet many companies still treat route planning as purely operational, missing the direct connection between route design and whether drivers stay or leave.

Because every percentage point improvement in retention saves thousands in recruitment costs, and route optimisation is one of the most underutilised retention levers available.

In our latest blog post, we explore how optimised delivery routes influence driver engagement, satisfaction, and performance, and provide some practical strategies to help you use route optimisation as a key retention tool.

Because it’s not just about keeping customers happy, you need to keep your employees happy, too.

Why Driver Retention Matters

Let’s be clear about what we’re talking about here. Driver retention is about keeping the drivers you’ve already got. Driver turnover reduction is about stopping them from leaving in the first place. Two sides of the same coin, really. You want to keep the people you’ve trained and invested in, rather than constantly starting from scratch.

When an experienced driver walks out the door, you lose more than just a person in a van. You lose:

– Years of route knowledge and knowing every shortcut in the area

– Relationships with customers who trust them

– The ability to handle tricky situations without needing to phone the office

– All those months of training you’ve put in

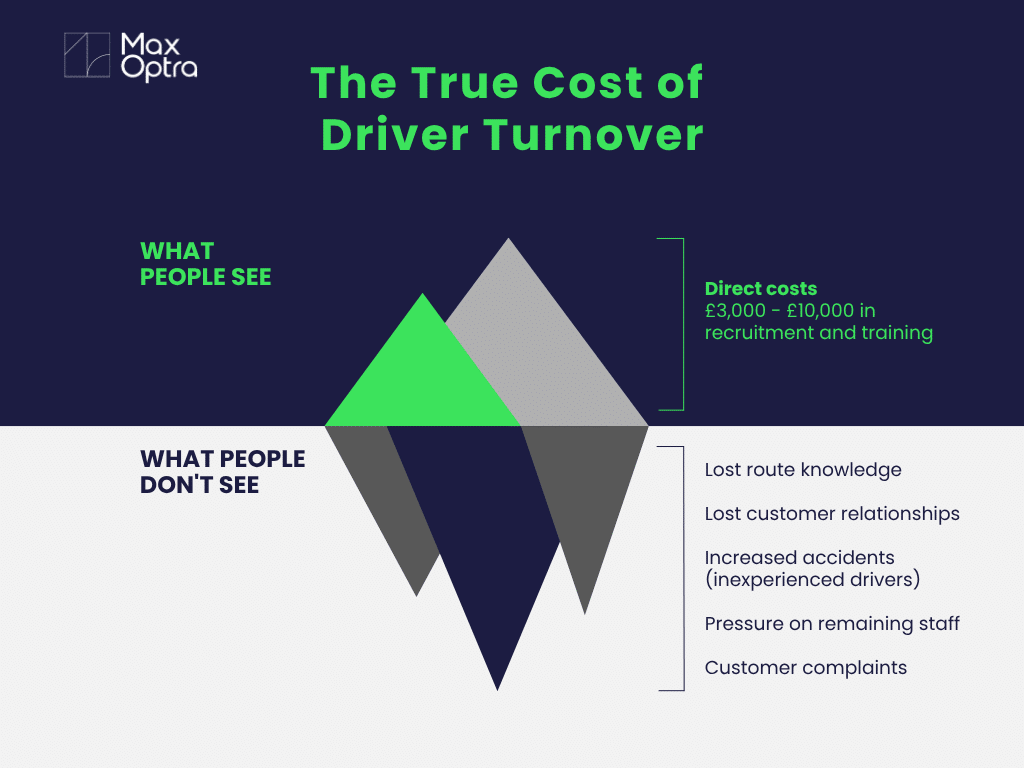

Research suggests the cost of hiring a new employee is between £3,000 to £5,000, reaching £10,000 in some sectors. Add in the increased chance of customer complaints, and the extra pressure on your remaining staff, and the real cost gets a lot higher.

Here’s the thing: poor retention creates a viscous cycle. High turnover means more inexperienced drivers. More inexperienced drivers means more accidents and worse service. Worse service puts more pressure on the drivers who stay. And then they leave, too.

Before you know it, you’re stuck in recruitment mode permanently, never building the stable, experienced team you actually need.

Key takeaways:

– Replacing a driver costs $6,000 to $12,000, but the real cost can be much higher.

– High turnover creates a vicious cycle that’s hard to break.

– Experienced drivers bring knowledge and relationships you can’t quickly replace.

The mechanics: How optimised delivery routes improve driver satisfaction & retention

So, how does better route planning actually help keep drivers? It’s not magic. When routes are badly planned, drivers deal with frustration after frustration, day after day, until leaving starts to look like the sensible option. Good route planning tackles these frustrations head-on, creating working conditions that people can actually stick with long-term.

Let’s break down exactly how this works.

Predictable schedules & home time

Good route planning means drivers can actually predict when their day will end. Not rigid schedules that ignore reality, but realistic routes that account for traffic, how long stops actually take, and proper breaks. When Tuesday’s route takes about the same time as last Tuesday (give or take the odd exception), drivers can plan their lives around work instead of work constantly messing up their plans.

Missing kids’ bedtimes. Cancelling plans at the last minute. Never knowing if you’ll finish at 5pm or 8pm. It wears people down. Route optimisation software uses past data and current conditions to create schedules that actually work most of the time, with realistic overtime built in when genuinely needed, not just because the planning is sloppy.

Reduced stress, fatigue, and burnout

Bad routes don’t just waste time. They actively stress drivers out. Being sent across town and back again for no reason. Hitting the same traffic jam every single day when there’s clearly another way. Getting a route that’s obviously impossible to finish on time. All of this builds up.

Route optimisation tackles this by working out the most sensible order for stops, avoiding known traffic problems during rush hour, and spreading the workload across the shift properly. That’s less time stuck in traffic, lower fuel costs, and drivers who aren’t completely knackered by the end of the day.

Fair workload distribution & equitable routing

When you’re doing routes manually, some drivers always seem to get the easy runs, whilst others get stuck with the nightmare territories. It might not be deliberate, but drivers notice. And they talk about it. And it breeds resentment.

Route optimisation can balance things out properly. The software can spread the workload evenly, making sure no one driver always gets the tight deadlines, difficult customers, or awkward parking situations. When drivers can see that route allocation is fair and based on actual logic rather than who the manager likes best, trust goes up. Job satisfaction goes up. People stay.

Clear performance visibility & feedback loops

Modern route planning tools give drivers proper insight into how they’re doing. On-time delivery rates, route efficiency, customer feedback, and how their day compared to what was planned. This means drivers can see where they’re doing well and where they might improve, rather than just getting pulled into the office when something goes wrong.

When drivers can track their own progress and understand how they contribute to the bigger picture, they feel more involved. They have more control over their work quality. And when there’s a good system for feeding back about problem routes or difficult customers, drivers become part of solving issues rather than just putting up with them.

Improved equipment use and downtime

Better routes mean less unnecessary driving, less sitting in traffic with the engine running, and generally less wear and tear on vehicles. Why does this matter for keeping drivers? Because nobody wants to spend their day in a van that’s constantly breaking down.

When you reduce vehicle wear through smarter routing, you can keep your fleet in better condition. Drivers notice when they’re given decent equipment to work with. It shows you actually care about their working conditions, not just hitting delivery numbers.

Key takeaways:

– Better routes mean predictable finish times, so drivers can actually plan their lives.

– Smarter routing cuts stress and fatigue by eliminating pointless driving and traffic jams.

– Fair workload distribution builds trust and stops resentment from building up.

– Performance visibility gives drivers control and involvement in their own improvement.

– Less vehicle wear means better equipment, which shows drivers you value their comfort.

Integrating Route Optimisation into your Driver Retention Strategy

Right, so you understand the theory. But how do you actually make this work in practice? The key is thinking about driver experience from day one, not treating it as an afterthought once the tech is installed. The companies that get this right involve drivers from the start and treat it as an ongoing process, not a one-and-done software installation.

Assess current route inefficiencies and pain points

Before you spend money on fancy new software, work out where your current approach is actually falling over. Your drivers are your best source of information here. Ask them directly:

– Which areas always have traffic problems?

– Where do the time estimates never match reality?

– Which customers are a nightmare to access, but nobody’s bothered updating the system?

– What genuinely winds them up about their current routes?

Then look at your data. Where do delays happen most often? Which routes are always running late? How many miles are you wasting with empty running between jobs? Where are drivers getting stuck waiting at customer locations? Put the driver feedback together with the hard numbers, and you’ll see exactly what needs fixing.

Select route optimisation software with driver-centric features

Not all route planning systems are the same when it comes to actually helping drivers. Look for:

– Real-time routing that adjusts when traffic or weather changes things

– Mobile apps that are actually easy to use, not a confusing mess

– Clear info about what’s changing and why, not just orders from a black box

– Fair workload features so nobody feels stitched up

– Dashboards where drivers can see their own performance

– Integration with whatever systems you’re already using

The driver interface really matters here. If the app is rubbish to use, drivers will hate it no matter how clever the routing algorithm is. The tech should help drivers do their job better, not feel like they’re being micromanaged by a computer that doesn’t understand the real world.

Pilot routes and driver collaboration

Don’t roll this out across everything at once. Start with a few routes and some drivers who are up for trying something new. Frame it as working together to find what actually works, not imposing a system from above.

Set up a proper driver group who can feed back on how it’s going. Meet regularly during the pilot to talk about what’s working and what isn’t. Actually listen and make changes based on what they’re telling you. When drivers see their input making real differences, they’ll support the system instead of resisting it. Plus, they know things about local roads and customers that no algorithm will ever figure out on its own.

Incentive alignment & recognition tied to routing metrics

When drivers stick to the optimised routes and hit their targets, recognise it. This doesn’t have to mean expensive bonuses (though those help). Sometimes it’s as simple as a shout-out at team meetings, friendly competitions between teams, or a “driver of the month” thing.

If you’ve got the budget, consider bonuses linked to following routes and keeping service quality high. Just make sure you’re rewarding the right behaviours. If you only reward speed, drivers will cut corners. If you reward sticking to good routes whilst maintaining standards, that’s what you’ll get.

A bit of gamification can work well too. Leaderboards, badges for consistent performance, team challenges. Keep it light and fun rather than Big Brother-ish. The goal is getting drivers engaged with better routing, not making them feel spied on.

Continuous monitoring, iteration, and route reviews

Route optimisation isn’t something you set up once and forget about. Roads change. Customer patterns shift. Drivers learn better ways of doing things. You need regular reviews of how routes are performing, looking at both the numbers and what drivers are saying.

Set up dashboards tracking the important stuff: on-time deliveries, route deviations, fuel use, idle time, and crucially, whether drivers are actually happy. When you spot problems (like one area always running late or one team’s satisfaction dropping), dig into it and sort it out.

Have quarterly sit-downs with your driver group to talk about route performance and get ideas for improvements. Make it a proper conversation, not a tick-box exercise. Your drivers are out there every day. They know things about traffic patterns and customer habits that your planning team will never spot sat in an office.

Key takeaways:

– Talk to your drivers first to find out what’s actually broken before buying software.

– Pick systems that drivers will actually want to use, not just ones with impressive feature lists.

– Start small with pilots and actually listen to driver feedback.

– Reward the right behaviours without making it feel like surveillance.

– Keep reviewing and improving based on what’s really happening on the ground.

Supportive retention strategies: Beyond routes

Better routes are brilliant for keeping drivers, but they’re not the whole answer. Even the most perfectly planned route won’t keep someone who feels undervalued or can’t see any future in the job. You need to look at the complete picture of what makes people want to stay.

Compensation and benefits are the foundation. Good routes make the day better, but fair pay shows you actually value the work. Think about retention bonuses for people who stick around, benefits that drivers genuinely need, and pay structures where people can see how experience and performance translate into earnings. Be transparent about it. Nobody likes feeling like pay decisions are random.

Career progression and training give people a reason to stick around long-term. Not everyone wants to be a manager, fair enough. But for those who do, they should be able to see how to get there. For drivers who want to stay on the road, create roles like:

– Trainer or mentor for new drivers

– Route specialist who knows their patch inside out

– Customer service champion

– Safety lead or compliance expert

Invest in proper skills development too. Advanced driving courses, customer service training, and qualifications in related areas. This all shows you’re serious about people growing their careers with you.

Culture and communication matter more than you might think. Regular one-to-ones shouldn’t just be about telling drivers what they’re doing wrong. Talk about concerns, get suggestions, and recognise good work. Some companies set up driver councils where drivers actually have input into decisions. Proper voice, not just pretending to listen.

Equipment quality affects every single day. Decent vans that are comfortable and well-maintained, with working air con and reliable sat navs, show you care about driver comfort. Not having to deal with constant breakdowns and repairs makes a massive difference to job satisfaction.

Work-life balance and flexibility are as important as pay for loads of drivers. Where you can, give some choice about shifts. Guarantee home time for long-haul work. Actually respect the shift boundaries you set instead of just ignoring them when it’s inconvenient. Let people sort family emergencies or doctor appointments without making them feel terrible about it.

Key takeaways:

– Fair pay and transparent pay structures are non-negotiable foundations.

– Give people career paths and development opportunities, even if they want to stay driving.

– Build a culture where drivers feel heard, not just managed.

– Quality equipment shows you care about daily comfort and safety, not just delivery numbers.

– Flexibility and work-life balance matter as much as money for most people.

Measuring success: KPIs and metrics

Of course, it’s important to actually measure whether your routes are working. Track both the operational numbers and whether drivers are happier. These measures show what’s improving, what needs work, and how to prove to the higher-ups that investing in retention was worth it.

Driver turnover rate

Work out your turnover rate by dividing the number of drivers who left by your average number of drivers, as a percentage. Track it monthly and yearly. Crucially, get a baseline before you change anything so you can actually see if it’s working. Split it between people who chose to leave versus people you had to let go. If fewer people are choosing to leave after you’ve sorted the routes, you’ve got proof it’s helping.

Driver satisfaction and Net Promoter Score

Regular surveys tell you how drivers actually feel about their jobs. Ask specific questions about route quality, whether workloads feel fair, equipment, management support, and overall satisfaction. A Net Promoter Score is simple: “How likely are you to recommend this company as a place to work?” on a 0-10 scale. 9-10 are your promoters (people who’d genuinely recommend you). 7-8 are passive (not unhappy but not enthusiastic). 0-6 are detractors (actively unhappy). Track how this balance shifts over time.

Average tenure and voluntary attrition

Average tenure tells you how long drivers typically stick around. If that number’s going up, your retention work is paying off. Voluntary attrition specifically tracks people who choose to leave rather than getting sacked, which tells you whether people think this is a sustainable job or just something to do until they find better.

Cost per replacement

Add up everything it costs to replace a driver: job ads, interview time, background checks, training, the productivity hit whilst they’re learning, and all the admin. Multiply that by how many people left, and you’ve got the real cost of turnover. When you can show that better retention is saving tens or hundreds of thousands a year, suddenly people pay attention.

Deliveries per driver and on-time delivery rate

These show whether better routes are actually making you more efficient, not just keeping drivers happier. Track average deliveries per driver per shift and what percentage arrive within the promised time. If both these numbers and retention are improving, you’re winning on all fronts.

Route deviation and driver idle time

Route deviation shows how much drivers are deviating from planned routes, either in order or in the path they’re taking. Some deviation will always happen (traffic, customer changes), but lots of it suggests routes that don’t work in reality. Idle time shows how much of the day is spent sitting around not making progress. Less idle time means better routes and drivers getting time back.

Fuel consumption

Fuel use per delivery or per mile shows route efficiency in hard cash. Better routes mean less pointless driving and less time spent in traffic jams. This metric connects route improvements to cost savings and environmental performance, which gives you extra reasons to justify the investment.

Key takeaways:

– Get baseline numbers before changing anything so you can prove what’s working.

– Track both the operational stuff (deliveries, on-time rates) and the people stuff (satisfaction, tenure).

– Work out the real cost of replacing drivers to show the financial benefit of keeping them.

– Watch route deviation and idle time to spot where routes don’t work in real life.

– Connect routing improvements to multiple wins: retention, efficiency, costs, and environmental impact.

Challenges, risks, and caveats

Let’s be honest. Route optimisation helps with driver retention, but things can still occasionally go wrong. Understanding the limitations helps you avoid the pitfalls that derail well-meaning projects.

Route optimisation is not magic

The software is only as good as the information you give it. Wrong addresses, service times that don’t match reality, traffic predictions based on old data – all of this produces less-than-perfect routes. The algorithm works with what it’s got. Put rubbish in, and you’ll rubbish out.

Before blaming the software when routes don’t work, check your data. Are customer locations actually accurate or just roughly right? Do your time estimates account for the difference between a quick doorstep drop and somewhere with security where you’re waiting 10 minutes just to get in? Have you updated traffic info to account for new roadworks or developments? Usually, bad results come from incomplete data, not broken algorithms.

Driver resistance to change

Some drivers will be suspicious of new route planning tech, especially if previous systems felt more like spying than helping. Drivers who’ve worked the same routes for years have strong opinions about the best way to do things, and they’ll resist routes that don’t match how they think it should work.

Deal with this through honesty and involvement. Explain how the system works, what it looks at, and what it can’t know. Accept that drivers know things about local roads and customers that no algorithm will figure out. Give them ways to feed that knowledge into the system. When drivers see their input actually improving routes, most of them switch from resisting to supporting.

Edge cases and unexpected events

Even brilliant route optimisation can’t predict everything. Last-minute additions to the delivery list, unexpected road closures, van breakdowns, drivers calling in sick and routes needing reshuffling, customers not being there when they said they would – these all need human judgement and flexibility.

Build in contingency planning. Make sure your system can handle mid-route changes and that drivers can easily report problems. Have clear procedures for when things don’t go to plan so drivers aren’t left figuring it out alone. Accept that some days will be chaos and focus on making sure your system handles exceptions gracefully rather than expecting perfection.

Capital and integration costs

Route optimisation software costs money, and getting it to work with your existing systems (warehouse management, customer databases, telematics) can add more complexity. How long it takes to pay for itself depends on your fleet size, how inefficient you are now, and how quickly you adapt to new ways of working.

Be realistic when making the business case. Factor in training time, potential productivity dips during changeover, and ongoing costs. For most operations with more than a handful of vehicles, the savings from efficiency and better retention justify the investment within 12 to 24 months. But don’t promise unrealistic payback that makes you look daft when reality takes longer.

Balancing fairness and efficiency

Trying to create a perfectly fair workload distribution can sometimes make routes less efficient. Making sure every driver gets an equal mix of easy and difficult stops, or rotating unpopular territories, might result in routes that aren’t as optimal from a pure efficiency viewpoint. It’s a genuine trade-off.

Most companies find that sacrificing a bit of efficiency for fairness is worth it because the retention benefits outweigh the marginal loss. But think about where you draw the line. If fairness constraints make routes noticeably worse, the business case gets weaker. Look for approaches that get fairness good enough whilst keeping most of the efficiency gains.

Key takeaways:

– Your results depend entirely on data quality – sort your addresses, times, and traffic info first.

– Handle driver resistance through honesty and involvement, not just imposing systems from above.

– Build in contingency for when things go wrong and don’t expect perfection.

– Be realistic about costs and timelines, and don’t overpromise.

– Accept some trade-offs between fairness and efficiency, finding the balance that works for you.

Conclusion

Driver retention challenges aren’t disappearing anytime soon. But the solution is more straightforward than many companies think. Better route planning tackles one of the main reasons drivers leave: the daily frustration of poor planning and chaotic schedules. When routes make sense, drivers finish on time, feel less stressed, and can see that someone’s actually thought about making their day manageable.

The numbers speak for themselves. Replacing drivers costs thousands. Route optimisation typically pays for itself just through efficiency gains, before you even count the retention benefits. Companies that treat route quality as a way to keep drivers, not just as an operations problem, end up with more stable teams and better service.

The logistics sector isn’t getting any easier when it comes to finding and keeping good drivers. Companies that create conditions people can actually sustain long-term will have a real edge. Better routes won’t fix every retention problem you’ve got, but they address fundamental frustrations that push people out the door.

Your next steps to driver retention

Ready to see how route optimisation can help you keep your best drivers? Talk to our team and find out where your current approach might be creating unnecessary hassle for your drivers.

Driver Retention and Route Optimisation FAQ

How quickly will route optimisation improve driver retention?

Don’t expect overnight miracles. Most companies start seeing retention improvements within 3 to 6 months of implementation, once drivers have experienced consistent benefits from better routes. The initial period might actually see some resistance as people adjust to new systems.

Stick with it, gather feedback, and make adjustments based on what drivers are telling you.

What if drivers prefer their own routes over the optimised ones?

This happens, especially with experienced drivers who know their areas well. The key is involving them in the process rather than forcing change. Often, driver-preferred routes contain local knowledge the algorithm doesn’t have (like a shortcut or a customer quirk).

Build in ways for drivers to feed this information back, and be willing to override the system when local expertise genuinely knows better. It’s about partnership, not dictatorship.

How much does route optimisation software cost?

It varies massively depending on fleet size and features. Small operations might pay a few hundred pounds monthly for basic software. Larger fleets with advanced requirements could be looking at several thousand.

Most providers offer tiered pricing based on vehicle numbers and features. Factor in implementation costs, training, and integration work too. Get quotes from multiple providers and be clear about what you actually need versus nice-to-have features.

Can route optimisation work for small fleets?

Absolutely. Even with just a handful of vehicles, better route planning reduces wasted time and driver frustration.

The percentage savings might be similar to larger fleets, though the absolute cost savings will obviously be smaller. Many providers offer solutions scaled for smaller operations. The retention benefits matter just as much whether you’ve got 5 drivers or 500.

What’s the minimum data quality needed for route optimisation to work?

You need accurate customer addresses (postcodes at minimum, full addresses better), realistic service time estimates for different delivery types, and some understanding of traffic patterns in your area.

If your current data is a mess, spend time cleaning it up before implementing optimisation software. Most systems can work with basic data and improve as you gather more, but starting with rubbish data will give you rubbish results.

How do I convince management to invest in route optimisation for retention?

Build a business case with hard numbers.

Calculate your current cost per driver replacement (recruitment, training, lost productivity). Multiply that by your annual turnover. Then show potential savings from even modest retention improvements. Add in efficiency gains (fuel savings, more deliveries per shift) and you’ve got a compelling ROI case.

If possible, reference case studies from similar companies in your sector.

What if our routes are too complex for software to handle?

Modern route optimisation handles surprisingly complex scenarios: multiple vehicle types, driver skills and certifications, time windows, priority deliveries, weight and volume constraints. What seems impossibly complex to plan manually is exactly what these systems excel at.

That said, there are edge cases and unusual requirements. Most good providers offer trials or demos where you can test with your actual data and constraints before committing.

Should we optimise all routes at once or phase it in?

Phase it in, definitely. Start with a pilot covering maybe 20-30% of your routes and drivers who are open to trying something new. Learn from that, make adjustments, build some success stories, then expand.

Rolling everything out at once is risky and makes it harder to identify and fix problems. Plus, you want some experienced drivers who can help train others once you expand.

How do we measure whether it’s actually helping with retention?

Track your turnover rate before and after implementation. Survey drivers specifically about route quality and schedule predictability. Monitor voluntary versus involuntary departures. Look at exit interview data for drivers who do leave.

If you’re seeing fewer people choosing to leave and feedback about routes improving, you’re on the right track. Give it at least 6 months before making judgments though.

What happens when a driver calls in sick and routes need reshuffling?

Good route optimisation software handles this.

You can quickly reassign stops across remaining drivers, with the system automatically recalculating optimal routes based on who’s available. Some advanced systems even have features for this specific scenario.

The key is having flexibility built in rather than rigid routes that fall apart the moment something changes.

Maxoptra System

© MaxOptra, 2023. Privacy Policy and Cookies