Cost Per Mile: What It Is and Why Every Fleet Manager Should Track It

For fleet and logistics managers, few metrics offer as much insight, and potential for optimisation, as cost per mile (CPM). Understanding the true cost to move goods from point A to point B is not just useful; it’s critical. Whether you’re managing a fleet of five or five hundred vehicles, tracking CPM helps sharpen your cost control, resource allocation, and decision-making capabilities.

This article explores what cost per mile is, how it’s calculated, why it matters, and how modern delivery operations can use it to drive efficiency.

What Is Cost Per Mile?

Cost per mile refers to the total cost a business incurs to operate a vehicle for every mile it travels. It’s one of the most fundamental metrics for fleet-based operations, yet often one of the most overlooked.

When calculated correctly, CPM provides a clear picture of both fixed and variable costs associated with fleet operations. This visibility enables logistics managers to understand where money is going, identify inefficiencies, and plan with greater accuracy.

Breaking Down the Components of Cost Per Mile

To accurately calculate CPM, you need to account for all the expenses involved in running your fleet. These costs typically fall into two categories:

- Fixed Costs These are expenses that remain constant regardless of mileage. Examples include:

- Vehicle depreciation

- Insurance

- Tax and licensing fees

- Lease or loan payments

- Salaries of salaried drivers or administrative staff

- Variable Costs These fluctuate depending on the number of miles travelled or deliveries completed:

- Fuel

- Tyre wear

- Vehicle maintenance and repairs

- Toll and parking fees

- Pay for hourly or per-drop drivers

To calculate CPM, use the following formula:

CPM = (Total Fixed Costs + Total Variable Costs) / Total Miles Driven

For example, if your total monthly costs are £20,000 and your fleet drives 25,000 miles in that period, your CPM is £0.80.

Why Cost Per Mile Matters

Tracking CPM isn’t just an exercise in accounting; it provides actionable insights that influence every aspect of delivery operations.

- Benchmarking and Budgeting Knowing your CPM allows you to benchmark performance across vehicles, regions, and time periods. This can inform budgeting, pricing strategies, and even staffing decisions.

- Fleet Optimisation By identifying the most and least cost-efficient vehicles or routes, you can make informed choices about maintenance, replacements, and route planning. This can lead to significant cost savings over time.

- Competitive Pricing Understanding the average delivery cost per mile helps ensure your delivery pricing remains competitive while still covering all operational expenses.

- Profitability Analysis Especially in sectors where delivery is a core service offering, CPM can be a direct indicator of profitability. The lower the CPM, the higher your margin potential per delivery.

- Sustainability Goals Efficient operations often correlate with lower fuel consumption and emissions. Monitoring CPM can therefore support your environmental and ESG targets by identifying areas to reduce unnecessary mileage or idle time.

Industry Benchmarks: What Is the Average Delivery Cost Per Mile?

The actual average delivery cost per mile can vary depending on region, industry, vehicle type, and delivery model. According to data from the American Transportation Research Institute (ATRI), the average cost per mile for commercial fleets in the U.S. was $1.855 in 2022, with fuel being the single largest expense. Source

In the UK, figures tend to be slightly lower due to shorter delivery distances and different cost structures, but rising fuel prices, insurance premiums, and regulatory requirements continue to place upward pressure on CPM.

For last-mile delivery services operating in urban areas, the CPM might be lower per trip but higher in terms of time and labour cost, given stop-start traffic, parking issues, and increased delivery frequency.

Using Cost Per Mile to Improve Delivery Operations

The real power of CPM lies in how it can guide operational improvements. Here are a few ways logistics and delivery managers are using CPM insights to their advantage:

Dynamic Route Planning

By comparing CPM across different routes and regions, managers can identify which journeys are more expensive than others. This insight supports dynamic route planning, allowing teams to balance cost-efficiency with delivery timelines and customer service.

Fleet Maintenance Strategy

Higher CPM values on certain vehicles may signal issues like poor fuel economy or frequent breakdowns. Identifying these trends allows for pre-emptive maintenance or retirement of inefficient assets.

Driver Performance Monitoring

Driver behaviour has a significant impact on fuel consumption and vehicle wear. Analysing CPM in conjunction with telematics data can highlight opportunities for driver training or rewards-based efficiency schemes.

Demand Forecasting and Resource Allocation

A clear picture of cost per mile delivery can also aid in forecasting. If certain delivery windows or customer segments consistently show higher CPM, it may be time to rethink resource allocation or introduce minimum order values.

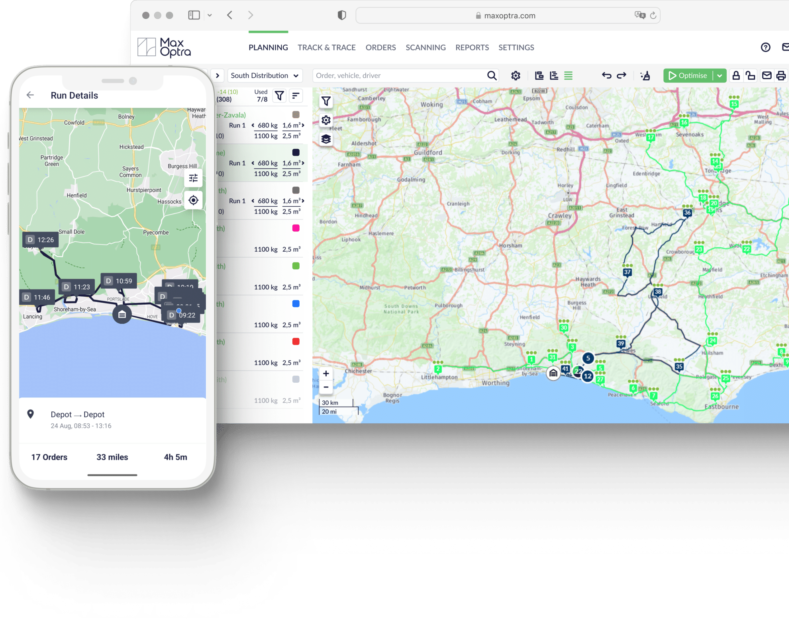

How Route Optimisation Software Supports Lower CPM

While tracking CPM is essential, reducing it is where the real value lies. Route optimisation software—like the solutions offered by MaxOptra—can be a game-changer here.

By intelligently planning routes that reduce mileage, limit idle time, and improve delivery drop density, businesses can significantly lower variable costs. In turn, this drives down the overall CPM.

Moreover, using real-time data, integrations with telematics, and automated reporting, fleet managers can make informed, data-driven decisions that improve cost efficiency over time.

Final Thoughts

Cost per mile isn’t just a number—it’s a strategic tool. For delivery and logistics businesses, understanding CPM means gaining control over the single largest operational cost: transportation. And in an industry where margins are often razor-thin, that insight is invaluable.

By breaking down fixed and variable costs, analysing trends, and implementing optimisation strategies, fleet managers can make smarter decisions that improve both efficiency and profitability.

Ready to Reduce Your Cost Per Mile?

Want to understand how your delivery operations stack up? MaxOptra’s route optimisation software helps logistics teams cut mileage, fuel usage, and delivery time—all contributing to a lower cost per mile.

Get in touch with us to see how we can support your goals.

FAQs: Cost Per Mile in Delivery and Logistics

What is a good cost per mile for delivery fleets?

A “good” CPM varies depending on your location, delivery model, and vehicle type. In the UK, many logistics operations aim for a CPM under £1.00, but high-efficiency fleets using electric vehicles or optimised routing may go lower.

How often should I calculate cost per mile?

It’s best practice to review CPM monthly or quarterly. However, in high-volume operations, weekly tracking can help spot trends and inefficiencies sooner.

What can increase my cost per mile unexpectedly?

Unexpected factors include fuel price surges, vehicle downtime, poorly optimised routes, and delays due to traffic or weather. Monitoring these alongside CPM can help you react quickly.

How does cost per mile differ for last-mile delivery versus long-haul?

Last-mile delivery often has a lower mileage per delivery but higher stop frequency and labour costs, leading to a different CPM structure. Long-haul deliveries generally have higher fuel costs but benefit from route efficiency over distance.

Can software really help reduce my CPM?

Yes. Route optimisation, telematics integration, and real-time scheduling can significantly reduce wasted mileage, fuel costs, and delays—resulting in a lower overall CPM.

Maxoptra System

© MaxOptra, 2023. Privacy Policy and Cookies